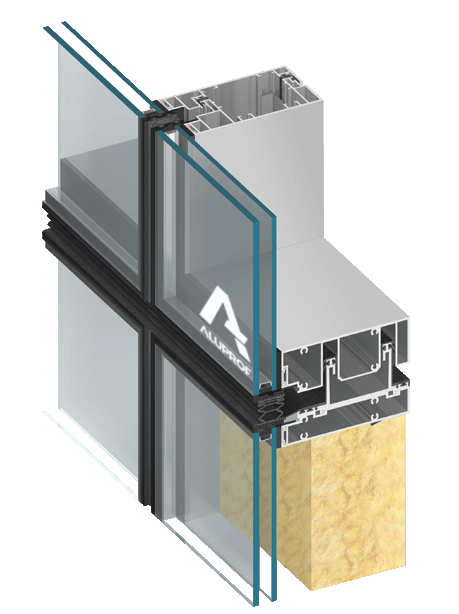

Unitized wall assemblies are fabricated and assembled off-site in a shop, but they are installed in the field on a more traditionally built structure.

Project Types

Unitized construction can work well in most market types across both residential and commercial construction. Low-rise and mid-rise projects can be well suited to modular. Unitized is more flexible overall and can be suited to a wider variety of project types. Large projects with a lot of square footage and tight schedules are well suited, including high-rise construction with unitized curtain wall.

When it comes to deciding whether a specific project is a good candidate for unitized construction, buildings with large exterior surfaces, repetition, simple geometry or even tight construction sites, are all good candidates.

Streamlined Benefits

Unitized construction offers owners, designers and contractors another option for the efficient design and construction of exterior wall systems. Prefabricated exterior wall systems can streamline construction schedules, reduce overall construction costs and improve exterior wall assembly quality. The use of prefabricated exterior wall systems is especially beneficial on construction sites with limited site access.

Unitized construction allows for quality control in a climate-controlled shop. It also lends itself to higher structural, thermal and moisture performance.

Pre-building exterior wall assemblies in a factory allows contractors and installers to quicky and more efficiently put the walls together on-site. Unitized construction can speed up the time it takes to clad the facade or elements of the facade of a building. It allows architects to incorporate more complex angles and curves into the facade, while the structure itself can remain relatively simple. This reduces particular labor costs, as much of the wall and details can be planned and organized during the preconstruction phase of the project, rather than in the field.

Growing Demand

Even with taking those points into consideration, more and more of their subcontractors are wanting to save labor in the field by unitizing during fabrication. Design lab is constantly innovating to find new ways to help our customers unitize, reducing project costs and speeding up construction lead times related to the facade of the project.

Conclusion

It is important to consider unitized wall construction because proper planning can yield significant savings in installation time and labor costs.”

Early engagement and collaboration are critical to success. Traditional design-bid-build delivery method and process does not align well with modular construction. The design has to be tailored (through collaboration and negotiation) to the capabilities and processes of the modular fabricator/contractor.

Unitized construction puts the fabricator and erector in a position to plan, design and engineer, then build. If you select the right fabricator early on, unitized construction can relieve a lot of stress, confusion, missed scopes of work, time, and surprise costs during the actual construction phase of project.