Mass timber, is a category of engineered wood products typically made of large, solid wood panels, columns or beams often manufactured off-site for load-bearing wall, floor, and roof construction.

Mass timber is engineered for high strength ratings like concrete and steel but are significantly lighter in weight. Mass timber products are thick, compressed layers of wood, creating strong, structural load-bearing elements that can be constructed into panelized components.

They are typically formed through lamination, fasteners, or adhesives. Mass timber can complement light-frame and hybrid options and is an environmentally friendly substitute for carbon-intensive materials and building systems.

What are Components and systems of mass timber?

Products in the mass timber family include

cross-laminated timber (CLT), dowel-laminated timber (DLT) glue-laminated timber (glulam), laminated strand lumber (LSL), laminated veneer lumber (LVL), parallel strand lumber (PSL), and nail-laminated timber (NLT).

The Advantages of Mass Timber

1. Fire Resistant

Large, solid, compressed masses of wood are actually quite difficult to ignite. In the case of fire, the outer layer of mass timber will tend to char in a predictable way that effectively self-extinguishes and shields the interior, allowing it to retain structural integrity for several hours in even intense fire.

All building materials have to meet code, and CLT meets code for fire safety.

2. Reduced Carbon Emissions

Most conventional lifecycle analysis counts wood supply as carbon-neutral, assuming it comes from sustainably managed forests; as we will see later, that’s not always a safe assumption.

Some amount of carbon embedded in the timber itself, where it is sequestered in buildings that could last anywhere from 50 to hundreds of years. Though the exact amount will depend on tree species, forestry practices, transportation costs, and a number of other factors.

3. Lower labor costs and less wastemuch of the labor and fabrication for CLT buildings is done at the factory, often using “computer numerical control” (CNC) machines to allow precision cuts.

If provided detailed plans by architects and designers, the factory can fabricate, e.g., a CLT wall exactly to specifications, with door and window openings in the right places and space for plumbing and electric. It virtually eliminates material waste — there are no door and window cutouts to throw away because the wood was never put there in the first place. With computer-guided fabrication, wood is placed only where it is needed.

Because these prefabricated pieces can be assembled a few at a time, in sequence, with relatively little labor, they can be shipped to the construction site on a just-in-time basis, avoiding massive on-site inventory and minimizing on-site disruption. Construction projects can be squeezed into tight, idiosyncratic urban spaces.

4. Earthquake Resistant

The performance of mass timber in earthquakes has been much tested (and tested and tested) and has proven remarkably good.

While concrete simply cracks in earthquakes, which means concrete buildings must be demolished and replaced, wood buildings can be repaired after earthquakes.

Mass timber is also lighter and can be built on urban land, e.g. brownfields, not suitable for heavy concrete construction.

5. Aesthetically Appealing

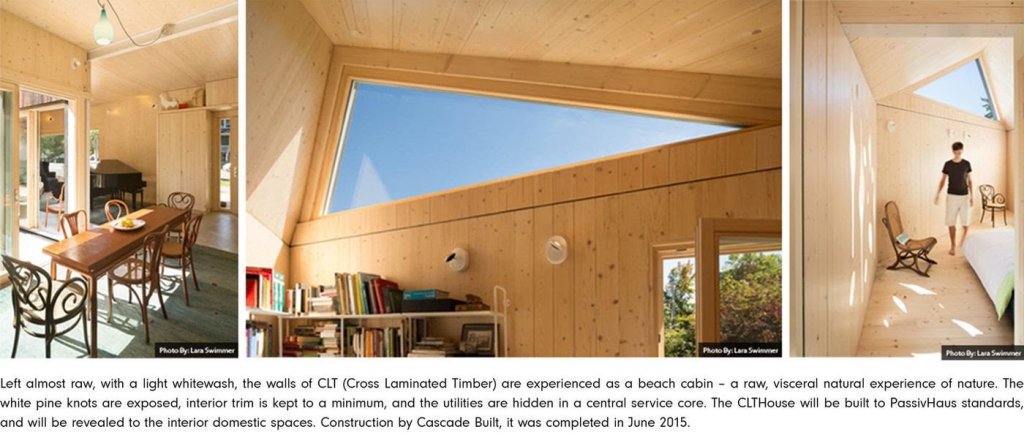

Wood is often left exposed in mass timber buildings — it doesn’t need to be wrapped or bolstered to meet code — and there is nothing quite so beautiful as large expanses of exposed wood. It is appealing on a primal level, a connection to nature. Wood is “nature’s fingerprint in buildings,” as Green puts it, and it has a deeply soothing effect.

Mass timber is also a good natural insulator. Softwood in general has about one-third the thermal insulating ability of a comparable thickness of fiberglass batt insulation, but about 10 times that of concrete and masonry, and 400 times that of solid steel. That makes it particularly good for windows and doors.

6. Good Forest Management

The forests on public lands badly need thinning, but there’s never enough funding. This has given Franz an idea: use weak and small trees, for which there is no other market, for mass timber. (Logs with tops as small as 4.5 inches will work.) A sufficiently large market for mass timber would create funding for thinning those trees out. As a bonus, Franz wants to use mass timber to build low-cost affordable housing on publicly managed land.

7. Job Creation

New demand for softwood could help reopen some of the closed mills and revive some of those communities, aligning their interests with a Green New Deal-style program of national revitalization.

8. There is no other choice

A more sustainable alternative must be found. And wood is the only material sufficiently abundant and renewable to do the job. We’ve got to figure out how to make it work.

Over the next 20 years, more than half of new buildings expected to 2060 will be constructed,” reports the United Nations Environment Program (UNEP). “More alarmingly, two-thirds of those additions are expected to occur in countries that do not currently have mandatory building energy codes in place.”

Reservations About Mass Timber

By and large, architects and builders are excited about mass timber, as are timber businesses and communities, timber-state politicians, climate hawks concerned about the carbon impact of building, and city officials looking for ways to accelerate decarbonization.

Mass timber must be coupled with sustainable forestry

There are many ways to reduce the environmental and climate impact of the building sector, some of which are arguably more important, at least for now, than the embodied carbon of materials. They include dense urban infill and multimodal transportation, more sustainable supply chains and construction practices, electrification of heating and cooling, and better building performance (efficient heat, light, and air circulation).

Mass timber appears to be the only viable alternative. And it’s cool! It cuts down on waste and costs, opens up the possibility of factory-based mass production of low-cost housing, and has sparked the interest and creativity of the building community.

Mass timber is worth celebrating and supporting, but it must always and everywhere go hand-in-hand with a renewed emphasis on climate-smart forestry. At the very least, everyone advocating for or involved in mass timber should be pushing for FSC certification standards to become a regulatory floor, not a voluntary ceiling.