Join my group board, Sustainabile Designs on Pinterest! https://pin.it/dcc6P1x

What is Sustainable Furniture?

Manufacturers create sustainable furniture using materials that have a minimal negative impact on the environment. Sustainable furniture uses:

- Woods or other materials that come from renewable sources

- Minimal chemicals that can pollute the environment

- Local material and/or manufacturing to save on transportation

Why is green furniture a better choice?

Eco-friendly furniture causes less damage to the environment and makes your home environment safer. When you choose eco furniture made with minimal amounts of chemicals, you’ll get less harmful pollutants, like volatile organic compounds (VOCs), released into your home’s air.Paints, fabrics, furniture, carpets and building materials can all release VOCs that cause allergies, migraines and asthma in people. According to a report by the European Respiratory Review, “The possible health effects of indoor VOC exposure are a cause for concern, given that people in general, and children in particular, now spend most of their time indoors.”

What are the best sustainable furniture choices?

The use of sustainable materials is just a part of making sustainable furniture. It is also vital to use responsible manufacturing practices as they have an immense impact on the environment. As such, these practices must be safe for the environment. This indicates that manufacturers must be mindful of checking carbon emissions and ensuring the environment is not polluted. They should also practice fair trade and preserve sensitive environments.

Upcycled Furniture

Whether you’re just following the sustainable and eco-friendly trend, or you want to create an efficient and green home from start to finish, you will want to pay attention to the sustainable furniture. The goal of this article is to explain why and gives you the options you need.

So what are the benefits of this type of furniture anyway?

- It’s made from eco-friendly materials.

- Furniture tends to be of higher quality.

- You show you care about your environment.

- Manufacturers avoid harmful materials and processes from choosing materials to delivery of the product.

- Sustainable means it’s durable and recyclable.

Without further ado, let’s explore all the types of sustainable furniture. We’ll leave it up to you to make the choice (there’s no way to go wrong), as well as give you some recommendations about where to find the furniture you like.

Typically, the materials used can be re-purposed or recycled. Previously-made pieces that are used to make new furniture can be referred to as sustainable. In addition, they have to be created from materials that can be easily renewed. For example, bamboo grows rapidly and can be very quickly replaced; therefore, it is considered a renewable resource.

Additionally, furniture is considered sustainable when environmentally-safe materials are used to create them. The manufactures also use low VOC finishes that do not emit dangerous chemicals to contribute to the safety of the furniture in everyday use.

The use of sustainable materials is just a part of making sustainable furniture. It is also vital to use responsible manufacturing practices as they have an immense impact on the environment. As such, these practices must be safe for the environment. This indicates that manufacturers must be mindful of checking carbon emissions and ensuring the environment is not polluted. They should also practice fair trade and preserve sensitive environments.2of 10

Upcycled Furniture

Upcycling is a technique that involves using discarded or old materials to create something reusable. The distinction between recycling and upcycling is simple. Recycling involves using consumer materials like glass, metal, paper, and plastic and breaking them down to make new consumer products that are typical of lower quality.

However, when an item is upcycled, the process does not involve breaking down any materials; the materials are simply refashioned. Furthermore, the quality produced from upcycled items has the same or even improved quality when compared with the original. This process is environmentally beneficial as it removes or saves materials from the landfills. It also encourages innovative thought processes and requires fewer resources than recycling.

Green Furniture Certifications

The best sustainable furniture choices are created from recycled items like salvaged wood, recycled textiles and reused materials like wood pallets. Additionally, natural materials like bamboo, rattan and seagrasses are excellent materials for furniture and home decor.Second-hand furniture and vintage pieces are also great green furniture choices. Pick vintage or antique pieces because they’re often handmade and built to last. Plus, their manufacturers often used fewer chemicals than modern manufacturers.

Carpet America Recovery Effort (CARE)

This partnership between industry and government increases carpet recycling and reuse to reduce the amount of old carpet going to landfills.

Cradle to Cradle (C2C)

C2C certified furniture can be dismantled to be repaired and recycled or so that parts can be replaced. This practice extends the life of the piece and makes a piece more sustainable because it keeps it out of a landfill.

Eco3Home

This hang tag certifies that the manufacturer was responsible in their sourcing and manufacturing and, additionally, that they can provide safety, health and environmental information for each registered product.

FSC (Forest Stewardship Council) Certification

FSC-certified furniture uses woods that are responsibly harvested and meet the requirements of the Forest Stewardship Council.

Green Housekeeping Seal of Approval

This seal is available for many categories like cleaning and beauty products, building materials, paints and coatings and appliances. In order to award approval, scientists and engineers evaluate a product’s packaging, ingredients, logistics and manufacturing.

Green Label Plus

Look for this tag to ensure that the carpet you are purchasing emits the lowest amount of chemicals on the market.

GREENGUARD Certified

Use this certification to find indoor goods like building materials and furnishings with low chemical emissions. It serves you and the environment because GREENGUARD certified goods do not affect air quality.

LEED (Leadership in Energy and Environmental Design) Certified

LEED promotes and awards certification for a whole-building approach to sustainability. To certify a building, LEED checks five categories: water savings, energy efficiency, sustainable site development, sustainable materials and good indoor air quality.

Low VOC

Check a product’s label. Look for low VOC because it means the product or finish is water-based or does not contain chemicals that can off-gas, or release into the air.

Rediscovered Wood Certification, Rainforest Alliance

This certification confirms that a piece of furniture actually uses reclaimed wood.

SBD (Sustainable by Design)

SBD gears their program towards furniture manufacturers to sustainably source and manufacture home furnishings.

Zero Waste to Landfill

This award goes to companies that send less than 1 percent of their waste to a landfill.

What’s next for sustainability?

No single industry can address the multiple issues involved with sustainability and the interdependencies that are part of this hugely complex system. It’s why collaboration between companies on a global scale is such an important goal.

However, we are seeing a shared agenda and awareness towards innovative solutions focused on minimising waste and toxicity, regenerating energy and natural resources, and an increasing collective awareness of our individual and business impact on the environment. For us, this is certainly a source of confidence and it’s helping shape our own sustainability goals – with strong partnerships and learning how best to meaningfully shape our future.

What are Living Facades?

Introduction

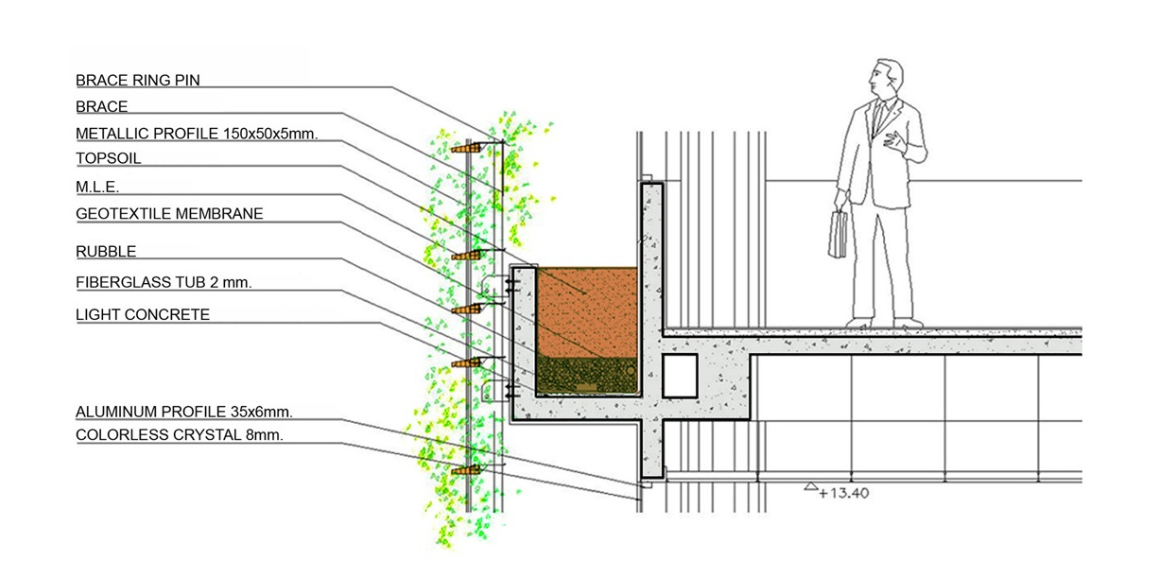

A living facade is a vertical surface incorporating vegetation into its structure or face to facilitate various aesthetic, environmental, social or economic functions and benefits. While research and studies on the subject are limited, it is thought that living facades could make a significant contribution to sustainability if properly integrated.

Also known as; living walls, vertical greenery systems, vertical gardens and vertical vegetated complex walls, they should not be confused with green walls (the process of allowing climbing plants such as ivy to scale a wall while being rooted in the ground).

Growing systems

Living facades can be grown and supported in two ways:

Both of these methods have advantages and disadvantages and many of the benefits attributed to living facades will apply to both. However, soil-based walls tend to be confined to free-standing walls or gardens, and due to their weight, are rarely used in conjunction with buildings. Therefore, this article will deal mainly with hydroponic walls.

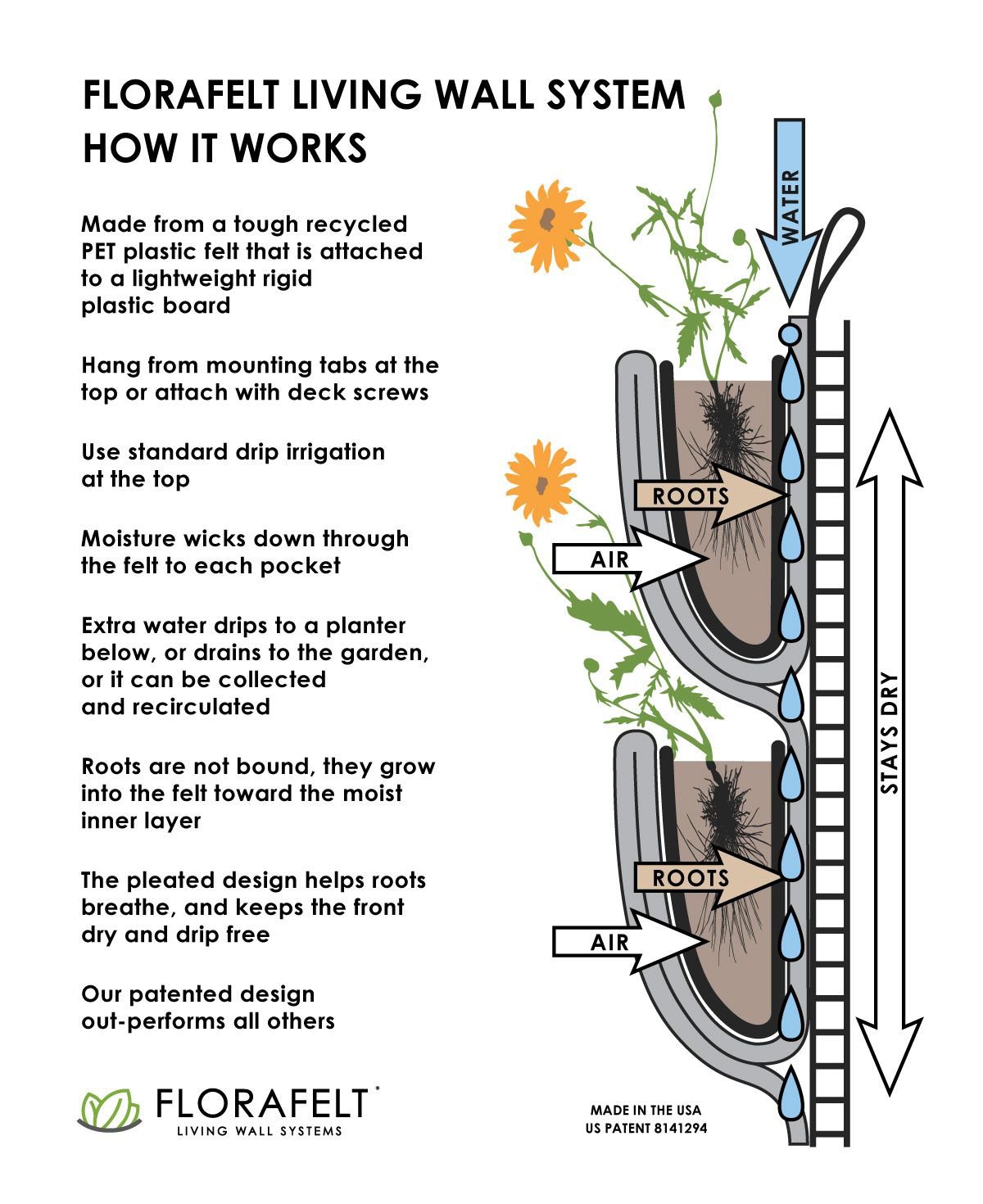

Hydroponics

The process of growing plants in sand, gravel, or liquid, with added nutrients but without soil.

The idea that vegetation can grow anywhere as long as it has water, light and nutrients is the basis of hydroponics and many living facade systems.

Vegetation on a living facade has to:

- Have a medium to be grown on.

- Be provided with enough water.

- Be provided with enough nutrients.

- Receive enough sunlight for photosynthesis.

Living facades depend on a mechanical system to provide water and nutrients. Many of these systems are complex, responding to temperature, direction of sunlight and other variables.

The rooting medium used can vary greatly depending on the preference of the living wall supplier and the needs of the plants. However, materials are generally chosen for their:

- Water and nutrient-carrying capacity (porosity).

- Ability for roots to take hold.

- Weight.

- Durability.

Common rooting media can include:

- Felt.

- Coco husk.

- Rock wool.

- Mineral wool.

- Porous foam.

- Wire mesh (with container for roots).

Structural systems

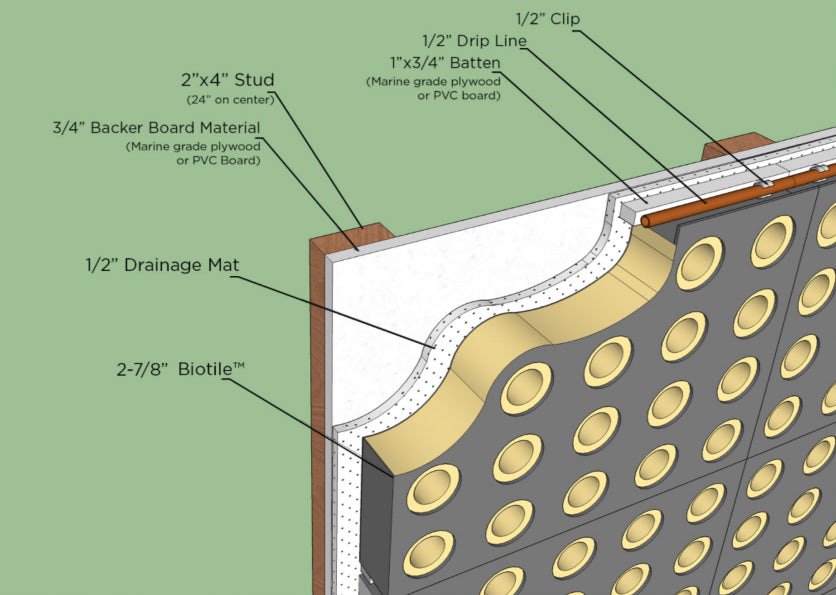

The structure of living facades varies between suppliers, however, there are three main structural systems, each with their own advantages and disadvantages:

Modular panel system

Panels of pre-planted vegetation are fitted to a support system that provides structure and a mechanical watering system. Pre-planting means that an instant green effect can be achieved upon completion. Composition of the modules will vary depending on the requirements of the vegetation, but will need to contain nutrients and material for the roots to hold. Soil can be used, but due to its weight it can only realistically be of use for small scale walls.

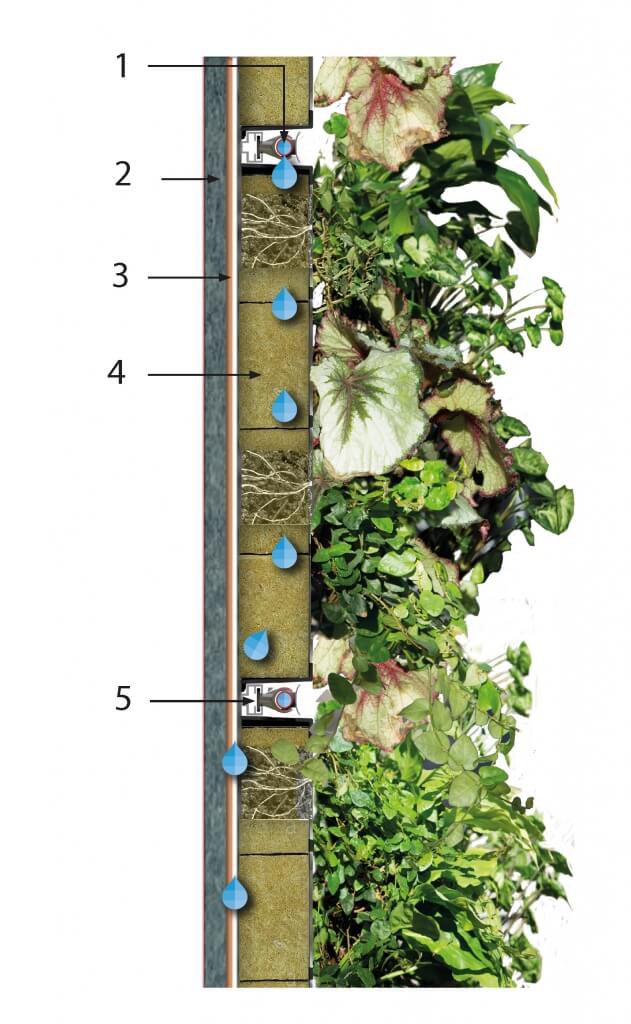

Synthetic felt

Pioneered by Patrick Blanc, this system uses synthetic felt as a base for vegetation, with water and nutrients provided mechanically. A metal frame is used for the structure, with a 10 mm PVC layer riveted to it and the felt stapled to this. The metal frame allows the structure to be attached to the facade allowing an air gap between the two layers which prevents vegetation from affecting the building structurally while aiding the thermal and acoustic properties of the facade.

The PVC layer prevents moisture escaping and provides rigidity to the entire structure. The polyamide felt layer consists of two overlapping sheets with various pockets that secure the plants. The choice of material is determined by its resistance to rotting and a high capillarity allowing water and nutrients to be distributed well. This facade has the benefit of only weighing 30 kg per metre squared.

Container and trellis

A series of containers house the plants with trellis in-between, allowing the vegetation to climb and create an uninterrupted face of vegetation. Water and nutrients can be provided mechanically with either a synthetic or soil based growing medium.

Positive effects

The majority of the positive effects of living facades are environmental, although aesthetic, social and economic benefits can also be identified.

Air quality

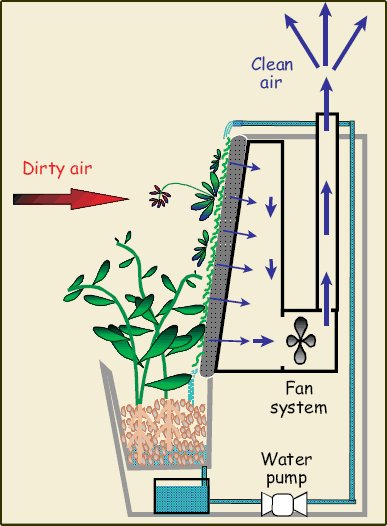

It has long been recognised that indoor plants can help improve the air quality in offices and an internal living wall can provide a similar effect and help rejuvenate ‘sick’ buildings. The plants absorb carbon dioxide and other particulates purifying the air.

The external air quality can also be improved by a living facade as it is able to absorb the carbon dioxide and pollutants from traffic. It has been shown that a living facade can have a major impact on the levels of nitrogen dioxide (NO2) and particulate matter (PM) in urban areas in which there are street canyons (where the height of buildings exceeds the distance between them). Street canyons cause the air to swirl and eddy around the vegetation enabling increased levels of particles to be absorbed.

A study carried out by Lancaster University found a reduction in street level concentrations of up to 40% for NO2 and 60% for particulate matter. With NO2 and particulate matter making up a large quantity of air pollutants, a reduction in concentrations of this magnitude would have a positive effect on air pollution in urban areas.

Thermal performance

The thermal effects of living facades are very similar to those of green roofs. ie, reduction in surface temperatures due to shading from vegetation, evapotranspiration and increased thermal mass. This can lead to a cooler internal climate and a reduction in urban heat island effect.

However, studies have shown that living facades may be more effective than green roofs in these areas.

Building performance

The surface temperatures and therefore the internal temperature of buildings can be affected by the presence of living walls and vegetation:

- The vegetation shades the solid wall behind it, preventing solar gains.

- Vegetation absorbs radiation therefore reducing reflection.

- The increased thermal mass of the vegetation and substructure reduces the flow of temperature through the building skin.

- Transpiration: the effect of water loss from vegetation by evaporation. Heat is carried away in the form of water vapour.

- Protection from cold winds.

Urban Heat Islands

An Urban Heat Island is the localised increase of temperature in urban centres as opposed to surrounding rural areas due to a profusion of heat retaining surfaces. It is thought that the reduction in surface temperatures due to living facades could help reduce the temperatures in urban areas.

A computer model based analysis at the University of Cardiff found a significant reduction of the temperature in urban canyons when building envelopes were fully ‘greened’. A similar conclusion was reached in a study by the University of Manchester, which found that an increase in green cover of 10% in urban areas could lead to a reduction in maximum temperatures.

Biodiversity

It is thought that living facades may contribute to an increase in biodiversity in urban areas by providing a habitat for insects and birds. Although specific testing on the biodiversity of living facades has not yet been thoroughly undertaken, there are examples of wildlife such as birds using living walls as their home. Any survey would have to acknowledge the potential disadvantages of increased biodiversity on a buildings facade.

Acoustic control

Vegetation is widely used to reduce the noise levels from busy roads or railway lines and it is thought that living walls may be used to control the acoustics of buildings. A study at the National University of Singapore found that living walls had a higher sound absorption coefficient than many standard building materials and that the noise reduction was also significant.

However, the study pointed out that these results varied greatly depending on the frequencies used, types of plant, percentage cover of wall and type of substrate. Further testing on actual buildings is needed to establish the true acoustic merits of living facades.

Aesthetics

Being in effect a vertical garden, the aesthetic qualities of a living facade are obvious and there are many examples where the primary objective is an aesthetic effect. Some of the visual benefits include:

- Rejuveinating bland facades.

- Softening of the urban landscape and allowing buildings to seem more ‘natural’.

- Changing aesthetics with season.

- The softening and diffusion of light, which can enhance internal spaces when used in conjunction with glazing.

Social

The effects of vegetation in urban areas on wellbeing are well documented and studies have found that people view greenery as very important in these areas.

Economic

Although full cost analysis has yet to be carried out, it is possible that living facades could have a beneficial economic impact on buildings:

- Reducing heating and air-conditioning costs.

- Adding commercial value to the building.

- Increased productivity.

Negative aspects

Living walls can require a high level of maintenance depending on the system chosen, and there have been documented problems with:

- Root rot.

- Plants dying.

- The need for trimming.

Future/incorporation with sustainability

There are many other areas of sustainability that living walls have the potential to be integrated with:

- Integration with air purification and ventilation, e.g. Queens University Biowall.

- Vertical agriculture/farming: vegetables or fruit could be grown on living walls and then harvested, increasing the surface areas available for agriculture.

- Water re-use: since living walls rely on mechanically supplied water, there is the opportunity to use grey water.

The need for more research

The lack of studies and research into living facades means that the true benefits and negative impacts are yet to be properly understood. Of the few studies available, most are either computer models, or testing carried out in controlled environments.

To truly understand the effects of living facades, long term testing needs to be carried out on buildings.

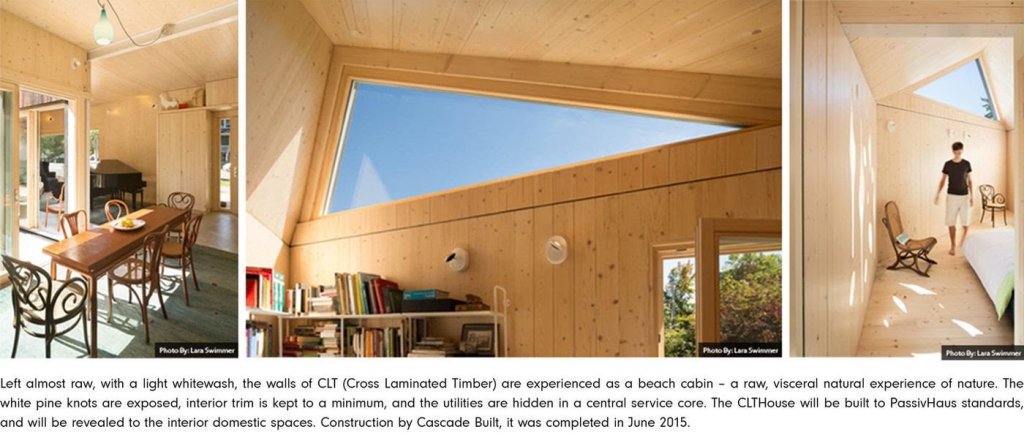

What is Mass Timber?

Mass timber, is a category of engineered wood products typically made of large, solid wood panels, columns or beams often manufactured off-site for load-bearing wall, floor, and roof construction.

Mass timber is engineered for high strength ratings like concrete and steel but are significantly lighter in weight. Mass timber products are thick, compressed layers of wood, creating strong, structural load-bearing elements that can be constructed into panelized components.

They are typically formed through lamination, fasteners, or adhesives. Mass timber can complement light-frame and hybrid options and is an environmentally friendly substitute for carbon-intensive materials and building systems.

What are Components and systems of mass timber?

Products in the mass timber family include

cross-laminated timber (CLT), dowel-laminated timber (DLT) glue-laminated timber (glulam), laminated strand lumber (LSL), laminated veneer lumber (LVL), parallel strand lumber (PSL), and nail-laminated timber (NLT).

The Advantages of Mass Timber

1. Fire Resistant

Large, solid, compressed masses of wood are actually quite difficult to ignite. In the case of fire, the outer layer of mass timber will tend to char in a predictable way that effectively self-extinguishes and shields the interior, allowing it to retain structural integrity for several hours in even intense fire.

All building materials have to meet code, and CLT meets code for fire safety.

2. Reduced Carbon Emissions

Most conventional lifecycle analysis counts wood supply as carbon-neutral, assuming it comes from sustainably managed forests; as we will see later, that’s not always a safe assumption.

Some amount of carbon embedded in the timber itself, where it is sequestered in buildings that could last anywhere from 50 to hundreds of years. Though the exact amount will depend on tree species, forestry practices, transportation costs, and a number of other factors.

3. Lower labor costs and less wastemuch of the labor and fabrication for CLT buildings is done at the factory, often using “computer numerical control” (CNC) machines to allow precision cuts.

If provided detailed plans by architects and designers, the factory can fabricate, e.g., a CLT wall exactly to specifications, with door and window openings in the right places and space for plumbing and electric. It virtually eliminates material waste — there are no door and window cutouts to throw away because the wood was never put there in the first place. With computer-guided fabrication, wood is placed only where it is needed.

Because these prefabricated pieces can be assembled a few at a time, in sequence, with relatively little labor, they can be shipped to the construction site on a just-in-time basis, avoiding massive on-site inventory and minimizing on-site disruption. Construction projects can be squeezed into tight, idiosyncratic urban spaces.

4. Earthquake Resistant

The performance of mass timber in earthquakes has been much tested (and tested and tested) and has proven remarkably good.

While concrete simply cracks in earthquakes, which means concrete buildings must be demolished and replaced, wood buildings can be repaired after earthquakes.

Mass timber is also lighter and can be built on urban land, e.g. brownfields, not suitable for heavy concrete construction.

5. Aesthetically Appealing

Wood is often left exposed in mass timber buildings — it doesn’t need to be wrapped or bolstered to meet code — and there is nothing quite so beautiful as large expanses of exposed wood. It is appealing on a primal level, a connection to nature. Wood is “nature’s fingerprint in buildings,” as Green puts it, and it has a deeply soothing effect.

Mass timber is also a good natural insulator. Softwood in general has about one-third the thermal insulating ability of a comparable thickness of fiberglass batt insulation, but about 10 times that of concrete and masonry, and 400 times that of solid steel. That makes it particularly good for windows and doors.

6. Good Forest Management

The forests on public lands badly need thinning, but there’s never enough funding. This has given Franz an idea: use weak and small trees, for which there is no other market, for mass timber. (Logs with tops as small as 4.5 inches will work.) A sufficiently large market for mass timber would create funding for thinning those trees out. As a bonus, Franz wants to use mass timber to build low-cost affordable housing on publicly managed land.

7. Job Creation

New demand for softwood could help reopen some of the closed mills and revive some of those communities, aligning their interests with a Green New Deal-style program of national revitalization.

8. There is no other choice

A more sustainable alternative must be found. And wood is the only material sufficiently abundant and renewable to do the job. We’ve got to figure out how to make it work.

Over the next 20 years, more than half of new buildings expected to 2060 will be constructed,” reports the United Nations Environment Program (UNEP). “More alarmingly, two-thirds of those additions are expected to occur in countries that do not currently have mandatory building energy codes in place.”

Reservations About Mass Timber

By and large, architects and builders are excited about mass timber, as are timber businesses and communities, timber-state politicians, climate hawks concerned about the carbon impact of building, and city officials looking for ways to accelerate decarbonization.

Mass timber must be coupled with sustainable forestry

There are many ways to reduce the environmental and climate impact of the building sector, some of which are arguably more important, at least for now, than the embodied carbon of materials. They include dense urban infill and multimodal transportation, more sustainable supply chains and construction practices, electrification of heating and cooling, and better building performance (efficient heat, light, and air circulation).

Mass timber appears to be the only viable alternative. And it’s cool! It cuts down on waste and costs, opens up the possibility of factory-based mass production of low-cost housing, and has sparked the interest and creativity of the building community.

Mass timber is worth celebrating and supporting, but it must always and everywhere go hand-in-hand with a renewed emphasis on climate-smart forestry. At the very least, everyone advocating for or involved in mass timber should be pushing for FSC certification standards to become a regulatory floor, not a voluntary ceiling.

What is Stucco Plaster?

Stucco or render is a construction material made of aggregates, a binder, and water. Stucco is applied wet and hardens to a very dense solid. It is used as a decorative coating for walls and ceilings, exterior walls, and as a sculptural and artistic material in architecture.

Stucco siding advantages:

- Durability.

- Stands up well to weather, wind and debris.

- Choice of any color and many textures.

- Can be formed to create decorative enhancements to the exterior.

- Low maintenance.

- Resistant to fire and insects.

- Quiets outside noise.

- Offers some insulation value.

R value

about 0.20 per inchTraditional stucco has a R-value of about 0.20 per inch. This means that stucco provides 20 percent of the insulation value of one inch of wood. Since the typical layer of stucco is usually less then an inch you can see that additional thermal barriers are needed to provide effective insulation

Layers

Three coat is the original stucco process, consisting of paper and wire, a scratch coat, a brown coat, and a finish, or “top” coat. In industry terms — lath, scratch and brown.

Durability

Stucco is a very durable finish material with a typical life span of 50-80 years or more. Although it is one of the most durable surfaces available, it also features the lowest annual maintenance cost when compared to other siding materials. Stucco is a natural material consisting of an aggregate, a binder, and water.

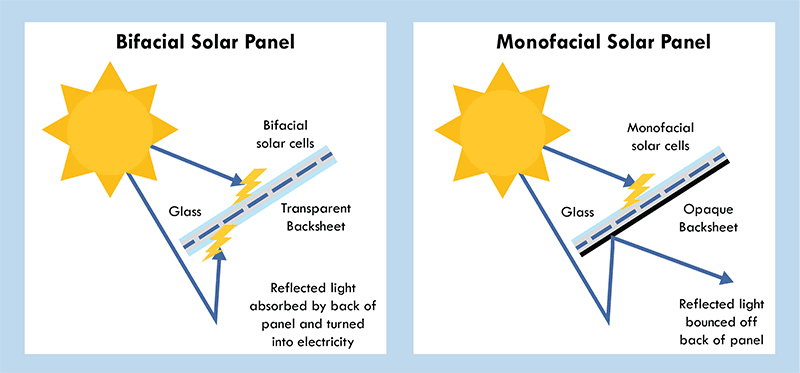

What are bifacial solar modules?

Bifacial modules produce solar power from both sides of the panel. Whereas traditional opaque-backsheeted panels are monofacial, bifacial modules expose both the front and backside of the solar cells. When bifacial modules are installed on a highly reflective surface (like a white TPO roof or on the ground with light-colored stones), some bifacial module manufacturers claim up to a 30% increase in production just from the extra power generated from the rear.

Design

Bifacial modules come in many designs. Some are framed while others are frameless. Some are dual-glass, and others use clear backsheets. Most use monocrystalline cells, but there are polycrystalline designs. The one thing that is constant is that power is produced from both sides. There are frameless, dual-glass modules that expose the backside of cells but are not bifacial. True bifacial modules have contacts/busbars on both the front and back sides of their cells.

How are bifacial modules installed?

The way a bifacial module is mounted depends on its type. A framed bifacial module might be easier to install than frameless, just because traditional mounting and racking systems are already adapted to framed models. Most bifacial module manufacturers provide their own clamps to mount their specific brand, taking away any installation hesitations

The way a bifacial module is mounted depends on its type. A framed bifacial module might be easier to install than frameless, just because traditional mounting and racking systems are already adapted to framed models. Most bifacial module manufacturers provide their own clamps to mount their specific brand, taking away any installation hesitations.

For frameless bifacial modules, the module clamps will often feature rubber guards to protect the glass, and special care must be taken to prevent overtightening bolts and damaging the glass.

The higher a bifacial module is tilted, the more power it produces from its bifacial properties. Bifacial modules mounted flush to a rooftop block any reflected light from reaching the backside of the cells. That’s why bifacial modules perform better on flat commercial rooftops and ground-mounted arrays, because there is more room for tilt and bouncing reflected light to the rear of the modules.

The mounting system itself can affect the performance of the bifacial modules. Racking systems with support rails usually covered by a monofacial module’s backsheet will shade back rows of bifacial cells. Junction boxes on bifacial panels have become smaller or separated into multiple units positioned along the panel’s edge to prevent shading, too. Mounting and racking systems specially formatted for bifacial installations take out the question of backside shading.

What is the outlook for bifacial modules?

The challenge with bifacial has always been the unpredictability of the power output because it’s dependent upon the substrate behind the modules—a white commercial roof, a dark comp shingle, grass, gravel. It’s hard to model what the module is going to produce. The financing community is coming around on bifacial and the cost structure is coming down. We’ll be hearing more about that technology in the coming two or three years. https://pagead2.googlesyndication.com/pagead/js/adsbygoogle.js?client=ca-pub-2829972634513519

Bifacial modules are the future of the industry. It inherited all the advantages of mono PERC modules: high power density resulting in significant BOS savings, high energy yield with better low light performance and lower temperature coefficient. In addition, bifacial PERC modules also harvest energy from the rear side, demonstrating higher energy yield. We think bifacial PERC modules are the best approach to realize lower LCOE.

Advantages of a Bifacial Solar Panel

Bifacial solar modules provide absolute benefits over regular solar panels:

- Better execution

- Higher productivity

- More prominent profitability

- Tantamount expense with the standard ones

- Better than utilizing trackers

- More sturdy

- Saves space

Efficiency Comparison

The bifacial solar panels have the capacity to manufacture electricity from both sides and this is due to the reason that they have glass covers on both the upper and back sides. This additionally makes them relatively more profitable and productive than their counterparts.

Are Bifacial Solar Panels Right For Your Home?

Bifacial solar panels are on the ascent and have been in utilization for as long as a couple of years. However, relatively few private residential solar systems have had them being used. These panels have generally been utilized in large commercial establishments with space limitations. Altogether, these solar panels are an incredible decision for solar systems across Pakistan. The greater part of the rooftops in Pakistan have cement, concrete, or block rooftops which are not the proper reflective material for these panels but rather they at any rate increase the profitability. The marble rooftops or white painted rooftops are the finest establishments for the installation of these solar plates.

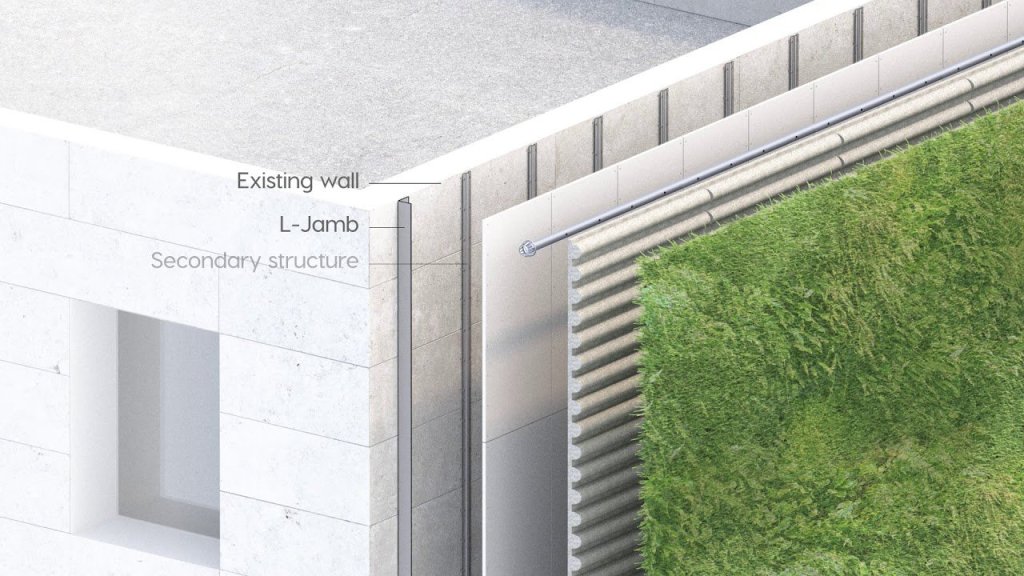

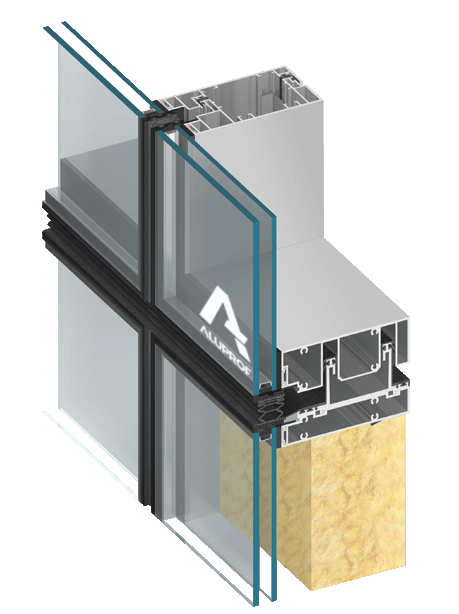

What are Unitized Facades?

Unitized wall assemblies are fabricated and assembled off-site in a shop, but they are installed in the field on a more traditionally built structure.

Project Types

Unitized construction can work well in most market types across both residential and commercial construction. Low-rise and mid-rise projects can be well suited to modular. Unitized is more flexible overall and can be suited to a wider variety of project types. Large projects with a lot of square footage and tight schedules are well suited, including high-rise construction with unitized curtain wall.

When it comes to deciding whether a specific project is a good candidate for unitized construction, buildings with large exterior surfaces, repetition, simple geometry or even tight construction sites, are all good candidates.

Streamlined Benefits

Unitized construction offers owners, designers and contractors another option for the efficient design and construction of exterior wall systems. Prefabricated exterior wall systems can streamline construction schedules, reduce overall construction costs and improve exterior wall assembly quality. The use of prefabricated exterior wall systems is especially beneficial on construction sites with limited site access.

Unitized construction allows for quality control in a climate-controlled shop. It also lends itself to higher structural, thermal and moisture performance.

Pre-building exterior wall assemblies in a factory allows contractors and installers to quicky and more efficiently put the walls together on-site. Unitized construction can speed up the time it takes to clad the facade or elements of the facade of a building. It allows architects to incorporate more complex angles and curves into the facade, while the structure itself can remain relatively simple. This reduces particular labor costs, as much of the wall and details can be planned and organized during the preconstruction phase of the project, rather than in the field.

Growing Demand

Even with taking those points into consideration, more and more of their subcontractors are wanting to save labor in the field by unitizing during fabrication. Design lab is constantly innovating to find new ways to help our customers unitize, reducing project costs and speeding up construction lead times related to the facade of the project.

Conclusion

It is important to consider unitized wall construction because proper planning can yield significant savings in installation time and labor costs.”

Early engagement and collaboration are critical to success. Traditional design-bid-build delivery method and process does not align well with modular construction. The design has to be tailored (through collaboration and negotiation) to the capabilities and processes of the modular fabricator/contractor.

Unitized construction puts the fabricator and erector in a position to plan, design and engineer, then build. If you select the right fabricator early on, unitized construction can relieve a lot of stress, confusion, missed scopes of work, time, and surprise costs during the actual construction phase of project.

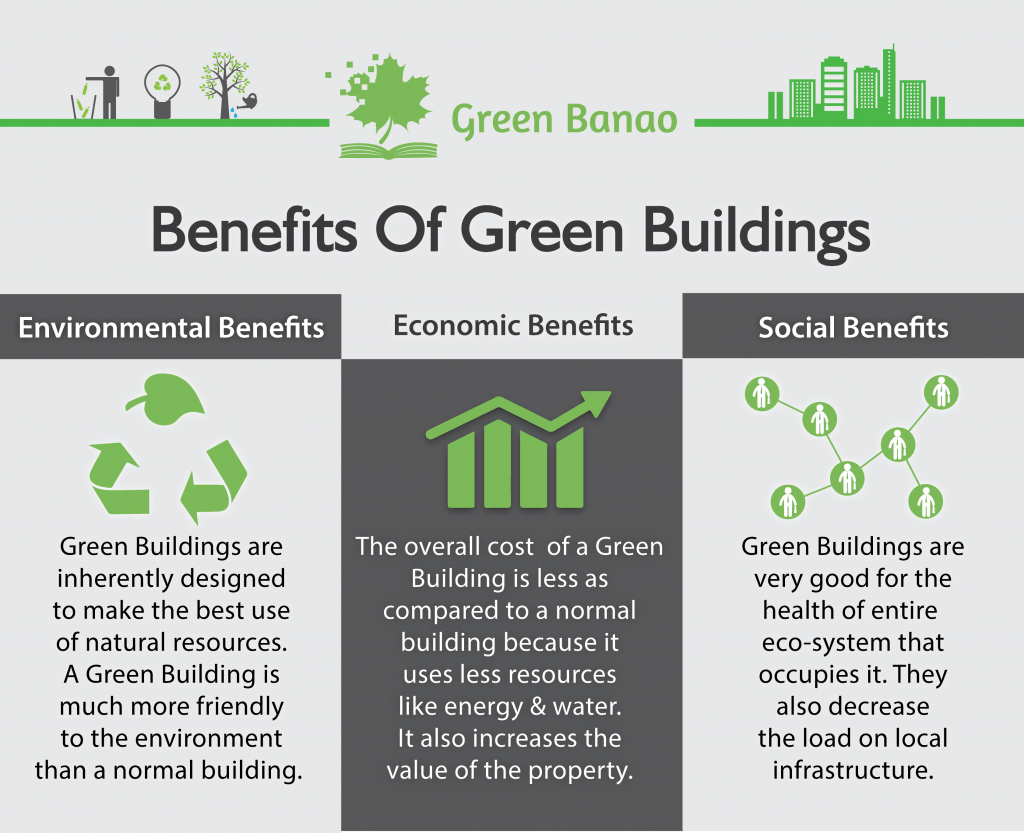

What are Green Buildings?

A ‘green’ building is a building that, in its design, construction or operation, reduces or eliminates negative impacts, and can create positive impacts, on our climate and natural environment. Green buildings preserve precious natural resources and improve our quality of life.

Features of Green Buildings

There are a number of features which can make a building ‘green’. These include:

- Efficient use of energy, water and other resources

- Use of renewable energy, such as solar energy

- Pollution and waste reduction measures, and the enabling of re-use and recycling

- Good indoor environmental air quality

- Use of materials that are non-toxic, ethical and sustainable

- Consideration of the environment in design, construction and operation

- Consideration of the quality of life of occupants in design, construction and operation

- A design that enables adaptation to a changing environment

Benefits of green buildings

The world over, evidence is growing that green buildings bring multiple benefits.

They provide some of the most effective means to achieving a range of global goals, such as addressing climate change, creating sustainable and thriving communities, and driving economic growth.

The benefits of green buildings can be grouped within three categories: environmental, economic and social. Here, we provide a range of facts and statistics from various third-party sources that present these benefits.

Highlighting these benefits, and facilitating a growing evidence base for proving them, is at the heart of what we do as an organisation.

What are Metal Cladded Facades?

The study of metal cladding is significant because this method of corrosion protection and wear protection is generally very reliable and cost-effective.

Metal cladding is a type of protective coating, where the protective material such as metal powder or foil is bonded to a substrate by applying heat and/or pressure.

Why Metal Cladding is Significant?

The cladding protects from changes in temperature, wind, water absorption, sunlight and pollution –all of which can damage the structural integrity of a building and its aesthetics.

Metal cladding is very resistant to harsh weather conditions so can simply be cleaned to retain its good aesthetics.

Thickness of Metal Cladding

Gauge refers to the thickness of the metal panel and is represented in number form. Most metal roof and metal siding panels on the market are between 20- 29 gauge, with 20-gauge being the thickest and 29-gauge being the thinnest panels sold.

Types of Metal Cladding

The five most commonly used metals for cladding are

- Aluminum

- Aluminium is a lightweight yet strong material for cladding a house. As a soft metal, it has high formability, but thickness is important for greater durability and a longer lifespan.

Aluminium is among the most waterproof of cladding materials and protects against moisture problems, which makes it a good choice for coastal homes. Aluminium cladding requires minimal maintenance and can be repainted easily if requiredZinc

Aluminium is an abundant resource, however, it is non-renewable. On the sustainability upside though, it is reusable and recyclable and requires little energy to manufacture.

- Zinc

Zinc is highly versatile and an increasingly common sight in contemporary architecture. It is a soft and malleable material, which allows for flexible construction. Zinc is extremely durable and low maintenance, and its resistance to oxidisation – by forming a naturally protective layer, known as a patina – helps it achieve an average lifespan of approximately 60 to 80 years.

Zinc is also a sustainable choice, being a non-toxic, recycled and recyclable material. It also takes less energy to produce zinc than other principal metals.

- Copper

Copper is a timeless material that develops a beautiful patina and character with age, making it suitable for both traditional and contemporary homes. Copper’s warm bronze tones turn an iridescent brown through natural weathering, before developing a green patina.

Copper is lightweight and durable, which can be important on large buildings. It also has a very long lifecycle and needs no treatment or maintenance with wear and tear.

- Corrugated Steel

Corrugated steel is a lightweight, strong and durable material that weathers well. The wave-like pattern of corrugated steel has become a recognisable and timeless element in traditional and contemporary Australian architecture, having been used since the 1850s. Corrugated cladding adds depth and texture to a facade and is available in a variety of colours. It is also easy to maintain and long lasting.

- Corten Steel

Corten is a weather-resistant steel (copper-chromium alloy steel) that is more resistant to atmospheric weathering than other unalloyed steels. Its chemical composition reacts to pollutants in the atmosphere and promotes the early formation of a protective oxide film, which constantly regenerates over time. This patina develops as a reddish-brown layer and gains a darker hue with time.

Despite the look of corrosion, Corten has twice the tensile strength of mild steel, making it an ideal structural material as well as being used for cladding and other architectural features

Cost of Metal Facades

Estimating the cost of metal facades and installing processes depends on the type of area; It also affects the prices according to several factors, for example, climate, metal facade brand, type of building and at least the level of experts who want to operate. So, do not wonder if you find some of the offices which take such services for different customers.

The metal facade texture depends on the main and basic materials that are used for producing the components or other related facing items. These items are the main examples of used metals for cladding:

All of the listed metals have their exclusive properties and suitable for a kind of building. Of course, the weather and climate of the appropriate area are effective too, for example, the stainless steel is the best choice to use for buildings which locate at rainy areas.

The installation method of each metal follows a special way itself. Copper and stainless steel are two expensive metal facade for such departments on the whole market. This kind of metal recommends for some special building with exclusive usage and appearance such as reception halls and hotels.

How is metal cladding installed?

Metal cladding is installed by attaching interlocking horizontal or vertical panels to the exterior sheathing of your house, or by wrapping the house frame in a sheet of metal. Aluminium cladding is easier to install than steel, because it’s lighter. This can sometimes save costs, but aluminium cladding is also easier to damage during installation.

Maintenance

One of the great advantages of metal cladding is that it requires little maintenance other than a yearly wash. While it was once prone to fading, the metal used for cladding is now generally coated with a tinted weatherproof topcoat that should last for many years. Steel is vulnerable to rust, so be certain to address any chips that occur in the finish, and install aluminium instead if you live in a coastal area.

If your cladding is dented it can be repaired, but repairs that involve patching holes are more challenging and generally need expert help. These types of repairs may also be difficult to disguise.

Conclusion

Installing the bold metal clad in a building and make them stronger against the external items and issues, especially, in some of the areas with unsteady weather and air conditions is the best idea and increases the building’s lifetime.

Besides the modern appearance they give to the buildings, they will increase the level of resistance and durable. So, modern architects try to design such plans for different buildings with dissimilar usages such as residential, recreational, commercial, and also official. Of course, bold metal clad is more suitable for some specific residential departments such as Villa which are often located out of the city.

What is Metal Facade support structures

You surely have heard the name of metal facades that support structures as well! Due to their names, these materials support the main structure of the main facade, in the other hand, the cladding covers all the facade of the building to support the basic structure.

The metal façade panels have to install over the main facade of the buildings and play an important role in protecting it from weather changes and unstable air conditions. The structure of the metal facade contains a thin layer of insulate and some extra spaces that fill with a soft industrial material that protect the main facade; They do not allow any kind of damage. It mostly acts as a protector wall of the external spaces of the building.

Embellishing new faces of construction or refresh the whole existing building are two important purposes of metal cladding systems. Of course, recognizing to use the metal facades is the duty of an architect who is working on related project. He/she has to attend several factors to make the best decision:

- Architect has to save time

- Avoids delays during the working time

- Keeping under control costs at the project

- Ensuring about the appearance of the metal facade cladding

Choosing the most suitable color according to the type of department and the weather is another important factor that the architect has to pay attention.

P E B Structures

What is a PEB structure?

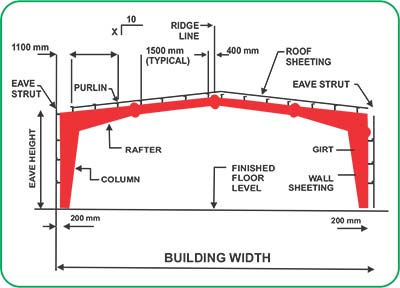

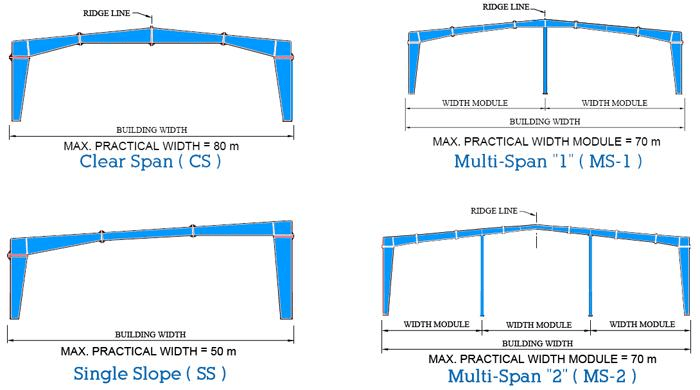

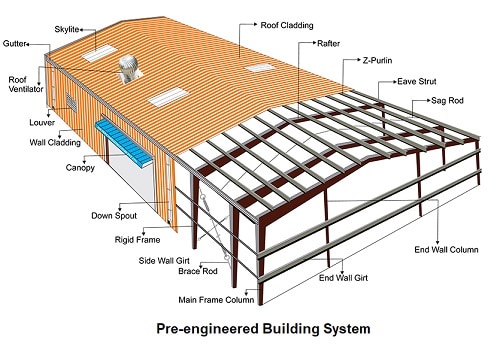

Pre Engineered Buildings (PEB) are the buildings which are engineered at a factory and assembled at site. Usually PEBs are steel structures. Built-up sections are fabricated at the factory to exact size, transported to site and assembled at site with bolted connections. This type of Structural Concept is generally used to build Industrial Buildings, Metro Stations, Warehouses etc

PEB are steel structures built over a structural concept of primary members, secondary members, roof & wall sheeting connected to each other & various other building components

The adoptability of PEB in the place of Conventional Steel Building design concept resulted in many advantages, including economy & easier fabrication. These type of building structure can be finished internally to serve any functions that is actually help in low rise building design. Examples of Pre-Engineered Buildings are warehouses, Canopies, Factories, Bridges etc.

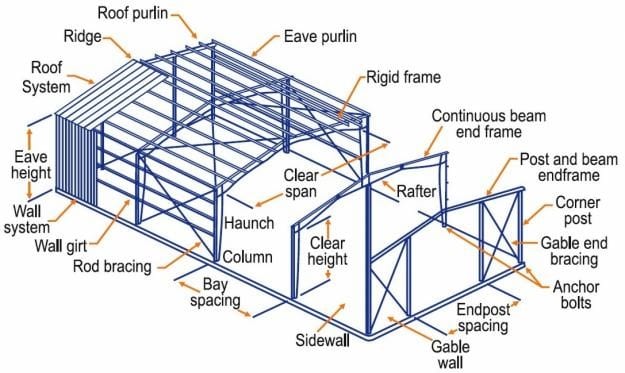

Components of PEB

Pre Engineered Buildings consist different steel structural member which are as follows,

Primary Frame: Primary framing of a PEB is an assembly of builtup I-Shaped steel members & that framing consist trusses or castellated beams etc.

Secondary Structural Elements: It is actually Cold Formed Members, which can be in diff. shapes like “Z”, “C” etc. In general known as “Purlins”.

Roof & Wall Panels : Tin shades & Curtain Wall made of Glass & Roll-formed steel sheets usually comes in this category , S

Sandwich Panels: Sandwich Panel is made of three layers , in which a non-Aluminum Core is inserted b/w two aluminum sheet.

Other Accessories: Mezzanine floors, Bolts, Insulation, etc.

Advantages of PEB:

There are many advantages of Pre Engineered Buildings, which are as follows,

Quality control is the main advantage as all the structural member are engineered beforehand, standards of different codes also taken into consideration & these components are made in factory under the supervision of Quality Control Engineer.

Lower cost due to the saving in design, manufacturing and on site erection cost.

Minimizing time of construction due to the use of software for design of the structural components.

Low Maintenance due to use of standard quality of paints over steel members , which increases the ability to withstand & finally the maintenance cost will be low as compare to conventional steel building.

Quick Erection, as all the members are Pre Manufactured & skilled labor is used for connections of different components.

Warranty on PEB, mostly warranty period of 20 years given by manufactures for PEB.

Disadvantages of PEB:

Although PEB have many advantages in the field of Industrial structure but still there are some demerits of Pre Engineered Buildings, which are as follows,

Rusting / Corrosion Sensitive, as if the quality of steel used or paint used for coating of steel members is not of good quality , than it can damage the structure and thus reduces the life of structure.

Insulation Cost, as insulating the building to an agreeable benchmark will furthermore add to your construction costs.

Appearance, Steel Sections can be unattractive when left exposed.

Design Methodology:

Method Used : Stiffness Matrix Method

Standard Code used :

AISC

ASCE

IS : 800

Software used : Staad.Pro v8i, ETABS, RAM Steel

Load Considerations & their Calculations : Loads considered in the PEB design are same as for general building structure. These are as follows ,

Dead load Calculations : It includes Self Wt. of Purlins , Roof & Wall Sheeting , insulation material & other structural component.

Live / Imposed Load Calculations : It should be Considered as per given in IS 875 (Part 2 ) for diff. type of

Wind Load Calculations : Consider the Basic wind Speed as per Area of that particular structure. Design wind Pressure is calculated as per IS 875 (Part 3) . Wind Load on Roof can be UDL & calculation for this can be done as per IS875(Part 3)

Seismic Load Calculations : Earthquake Loads affect the design of structure in areas of great seismic activity. The seismic load can be calculated as per IS 1893-2002(Part 1).

Other Moving Loads : It can be Moving EOT Crane load or Mono Rail etc.

Load Combinations : As per IS 1893 – 2002 (Part 1)

7(DL ± LL)

7(DL ± EL)

3(DL + LL ± EL)

Mechanism : For diff. Load Combinations structure should be checked by considering Internal work equal to External work and We will consider the following Mechanism,

Beam Mechanism

Sway Mechanism

Gable Mechanism

Combined Mechanism

Checks Made :

Effect of Axial Force : Max. Load should be checked with allowable load bearing of the section.

What is the cost of PEB?

The pre-engineered metal buildings stand for the buildings that are predesigned, pre-sized, and prefabricated. Generally, pre-engineered metal buildings costs start from $1395 and go up according to the size and customizations